The AutoSeal® FD 2096 uses patented pressure seal technology to efficiently process cut-sheet pressure seal forms in a mid-volume production environment, at speeds of up to 30,000 forms per hour. Its bottom-suction air-feed system provides accurate feeding and allows for continual loading of forms, dramatically reducing down time.

Set-up is quick and easy with rugged metal fold pates, clearly marked with both standard and metric markings, and fold rollers made of heavy-duty polyurethane foam, which eliminates the need for gap adjustments. The sealing unit utilizes an adjustable 17" ball transport deck for a smooth, reliable transition from the fold rollers into the sealer.

User-friendly features include sound-dampening fold plate covers for quieter operation, a 6-digit resettable LED counter, rugged locking casters, and a high-capacity 24" output conveyor which is collapsible for convenient storage when not in use.

Operating Features

Variable Speed: Large jobs are processed quickly at speeds of up to 30,000 forms per hour

Top-Loading Bottom Air Feed: The air feed deck accurately feeds forms, while allowing for continuous top feeding, with no need to stop and reload

Resettable Counter: 6-digit LED counter provides maximum audit control

Noise Reduction: Covers and fold plates are insulated to reduce operating noise

Rugged Construction: Designed for mid-volume production environments Casters for Easy Transport

Folding Features

Heavy Duty Fold Rollers: Polyurethane foam rollers eliminate the need for gap adjustments

Rugged Fold Plates: Metal fold plates feature metric and standard scales for easy fold setting

Air-Feed Pump: Fully enclosed

Rotating Air Suction Drum: Located on the feed table, separates sheets for accurate feeding

User-Friendly Adjustments: Fold plates feature a 7-point quick-release fold stop, skew adjustment and fine tuning knob

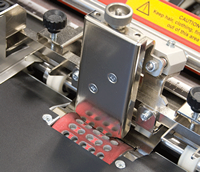

Sealing Features

Pressure Rollers: Precision ground clutching four-roller system

Ball Transport Deck: Adjustable 17" ball-deck provides smooth, efficient transport from the folder into the sealer

Fault Detection: Infrared sensor located at the infeed of the sealer detects any faults and sends a signal to stop the folding unit

Plexi-Cover: Hinged with a handle to allow quick access to the sealing area. Includes safety interlock to stop the system when opened

Static Eliminator Brush: Located on the exit of the sealer to reduce static electricity and assist in the neat, sequential stacking of forms onto the conveyor

Conveyor Features

24" Outfeed Conveyor: Includes speed control and run-out switch for easy unloading of processed forms

Adjustable Stacking Wheels: Help to keep processed forms in a neat, sequential order

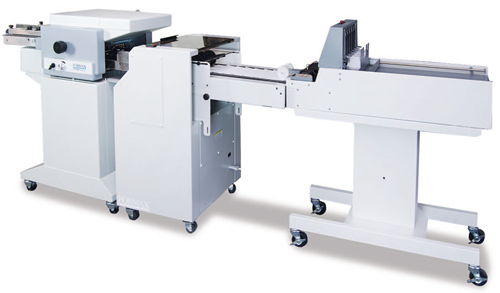

V-Stack36 Stacker: Vertically stacks up to 22" of folded documents, making them easier to unload

Center Slitter: For applications including 2-up postcards

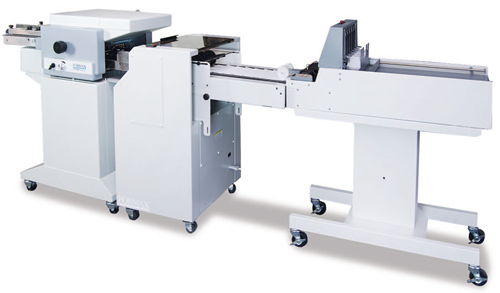

FD 2096 Pressure Sealer, in-line with optional V-Stack36 Vertical Stacker and V-Stack36-10 Adjustable Stand

Hopper Capacity

Up to 350 sheets 24#

Variable Speed

Up to 30,000 forms per hour

Usage

Mid-volume tabletop

Paper Size

Up to 12" wide, up to 17" long

Dimensions

Conveyor Extended: 86" x 28" x 42" (L x W x H)

Conveyor Closed: 64" x 28" x 42" (L x W x H)

Weight

450 lbs

Power

120V 60Hz, 30Amp, single phase

Power Plug

NEMA L5-30P

All technical data and dimensions are approximate values

Girard’s offers the option to lease your equipment. Help make that purchase more affordable with low monthly payments.

If you would like more detailed information please contact one of our .

Girard’s Business Solutions, Inc.

11910 12th Ave South

Burnsville, MN 55337

Phone:

(952) 890 - 4827

(800) 536 - 4472